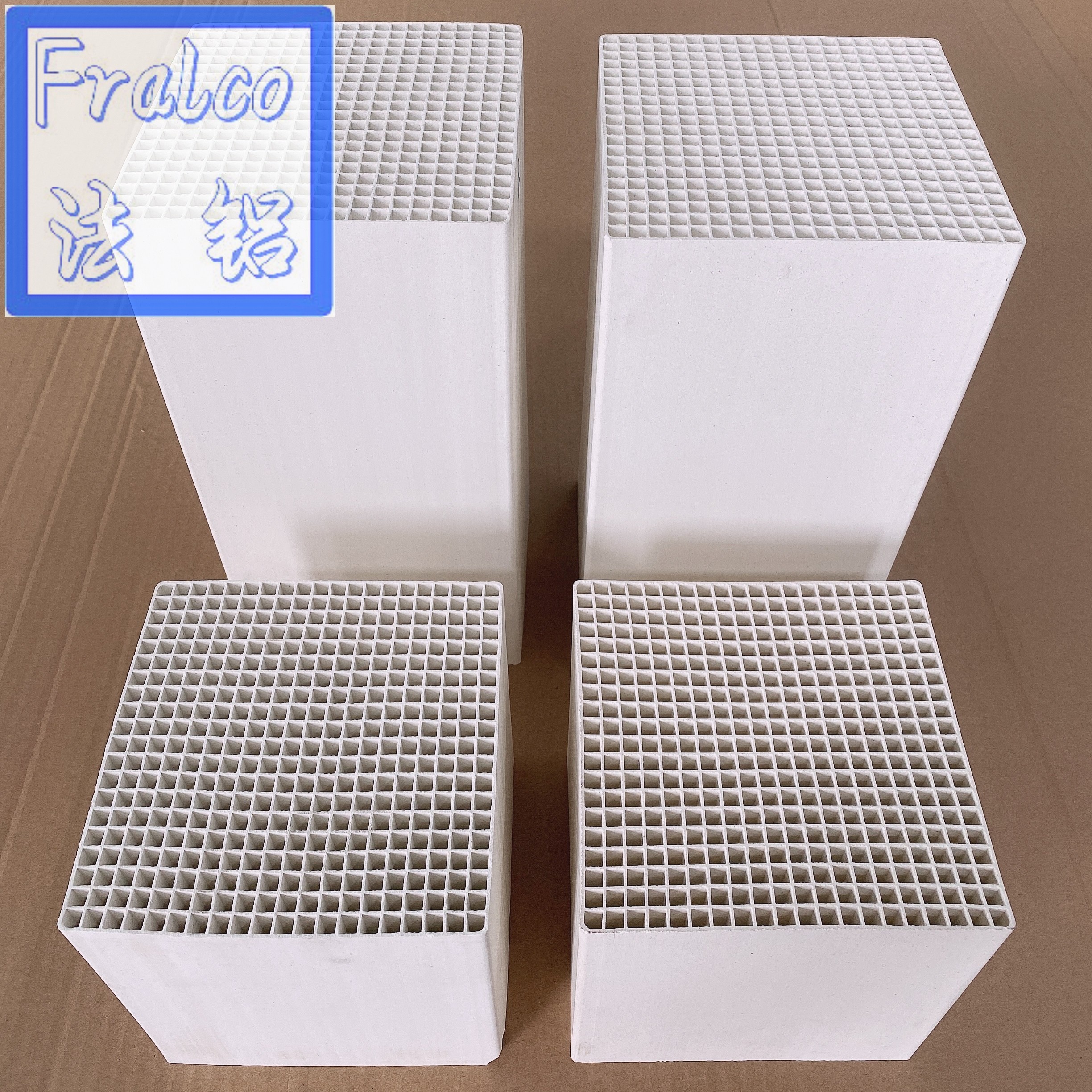

Honeycomb Ceramic

Application:

Honeycomb ceramic heat accumulator is also a high temperature combustion heat accumulator, which is the key and core component of high temperature combustion technology.The honeycomb ceramic heat storage body is widely used in smelting, heat preservation furnace and heat treatment furnace in iron and steel, nonferrous and chemical industries. It is the core component of regenerative burner. The technology can save fuel up to 40~70℃, increase furnace temperature more than 15℃, NO2 discharge less than 100 ppm, flue gas temperature less than 150℃, greatly alleviate energy shortage.

After being coated with a catalyst, Honeycomb Ceramic product is applied to a catalytic converter for the purification of gasoline vehicle exhaust gas, and catalytically converts and purifies the exhaust gas emitted by the automobile. The dimensions are 400 holes / inch, 600 holes / inch, which meet the Euro VI emission standards.

Properties:

Thin hole wall; Large specific surface area;

Small back pressure ; High compressive strength;

Small coefficient of thermal expansion; Good Thermal shock resistance ; Good compatibility with various catalyst active components;

Good cold start performance, low light-off temperature, fast heating, low gas resistance and high conversion efficiency.

Product Details:

|

Performance |

Corundum - mullite |

Mullite |

Cordierite - mullite |

|

Bulk density (g/cm3) |

≥0.8 |

0.6~1.1 |

0.6~0.9 |

|

Thermal expansion coefficient |

≤6 |

≤5.5 |

≤3 |

|

Specific heat capacity |

≥800 |

≥800 |

≥750 |

|

Heat shock resistant temperature |

≥300 |

≥300 |

≥400 |

|

Load softening temperature |

≥1500 |

≥1450 |

≥1350 |

|

Thermal conductivity |

>10w(m.v.) |

>10w(m.v.) |

>10w(m.v.) |

CONTACT INFORMATION

Contact

OFFICIAL APPLET

Applet

Welcome to our official applet

ONLINE MESSAGE

Message